When I began my traineeship as an artisan coach builder, I had the privilege of working on classic vehicles like the Morgan 4/4 Roadster.

Morgan – body & Panel repairs

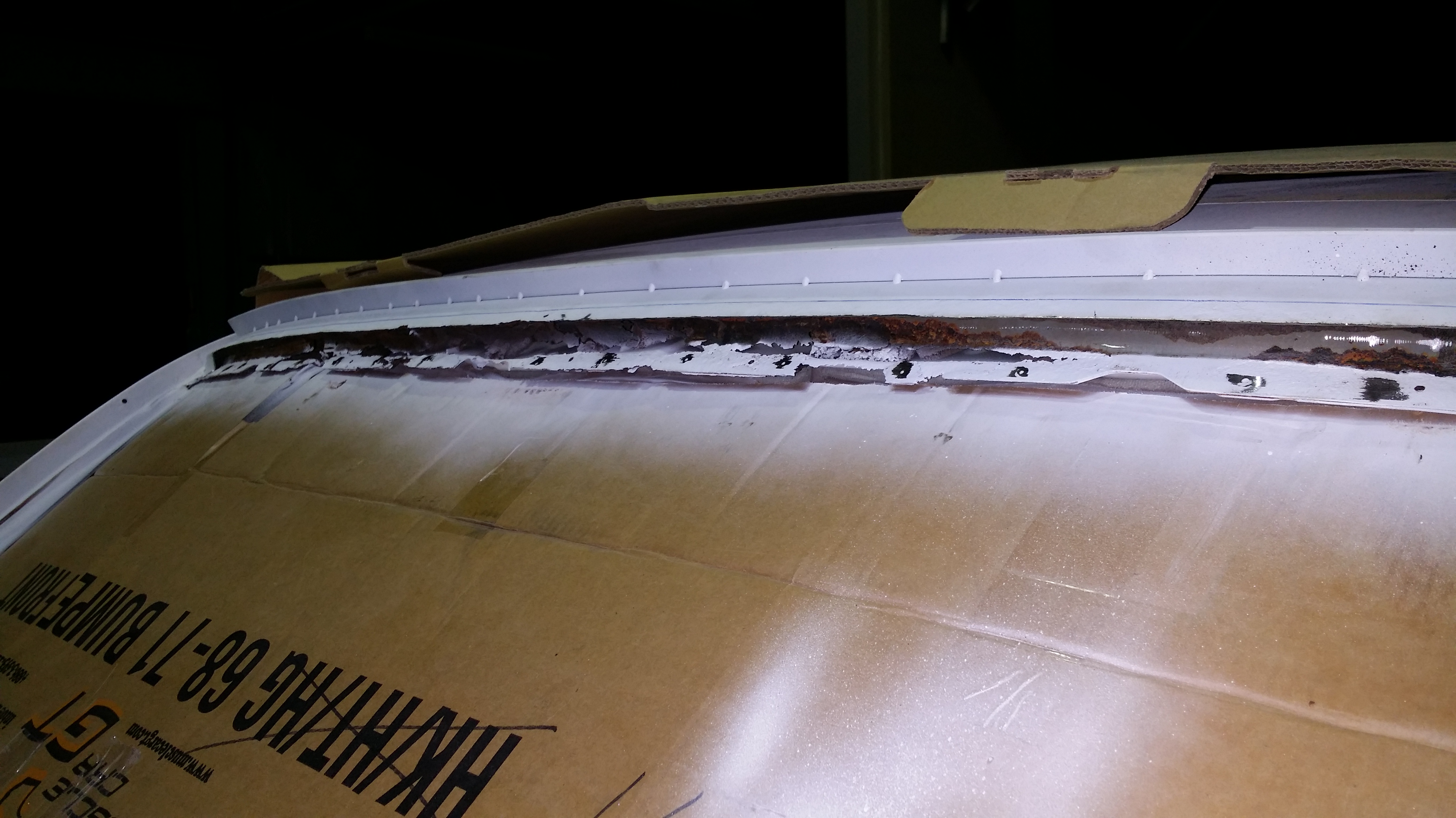

One of the first steps in the repair process involved squaring and securing the timber body frame to the chassis. Then, the body panels were fitted to ensure proper alignment and functionality.

The vehicle was initially delivered without any attached parts, exposing the timber frame.

We fitted the rear quarter panel to determine the extent of the sill panel and the position of the rebate joint.

Before commencement of repairs, we also trial fitted the lower section of the front cowl panel. Subsequently, we fabricated the sill panel section and integrated it with the front cowl panel.

To ensure a seamless integration, we notched the timber body frame to allow for the smooth connection of the quarter panel and sill panel section.

The quarter panel section was stepped to create a rebate that would overlap with the cowl panel (sill panel section) and provide a flush finish.

The finished joint between the cowl panel and the quarter panel (sill panel sections), as originally manufactured by Morgan.

We repeated the process by notching the timber body frame at the dovetail end to ensure the smooth integration of the quarter panel and dovetail panel.

The rear section of the quarter panel section was also stepped to create a rebate for the dovetail panel, resulting in a flush joint between the two sections.

The finished joint between the dovetail section and the quarter panel.

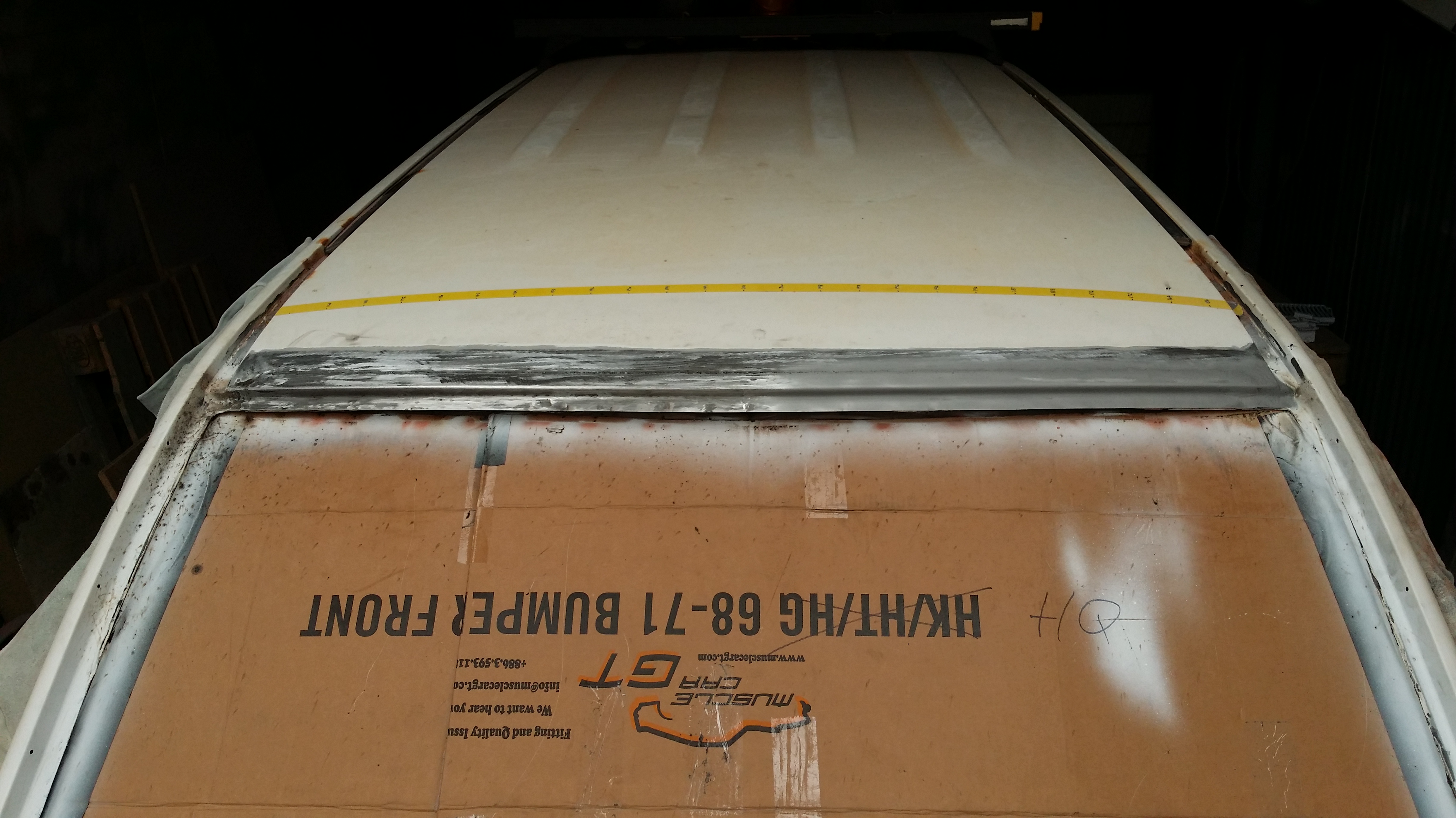

Morgan – panel alignment

Once the repairs were complete, we performed a post fitment and alignment of the body panels on the Morgan. This step was crucial before proceeding with painting as it ensured uniform separation between the panels, eliminating the risk of binding or scuffing with adjacent panel sections.

Before fitting and aligning the reproduction quarter panels, we made necessary alterations to the timber frame.

During the fitting of the front panels, we tweaked and laser-leveled the chassis to achieve improved gaps and alignment.

We carefully fitted and adjusted the fenders to ensure a consistent gap between adjacent panels.

The rear quarter panels were installed along with the doors, and their contour was manipulated to create a uniform seal.

We also manipulated the rear dovetail panel to fit the new timber frame.

The final result was a well-finished vehicle body with uniform gaps, achieved without forcing the parts into position.

Morgan – Repair Panels

Fortunately, for this particular vehicle, we had a limited number of repair panels to fabricate as the owner provided aftermarket quarter panels.

The new sill panel sections fabricated in house.

Front valance panel was fabricated in house with a stainless steel wired edge.

Fortunately the customer was able to source the new fabricated quarter panels from the UK.

Morgan – Bespoke Panel Fabrication

When the vehicle initially came to us, it was missing two important panel sections—the front and rear valance panels. Upon its return, after having the mechanical items reinstalled, we fabricated and installed a bespoke center console.

The Morgan did not have a front valance panel originally, but the owner wanted to add front lights without compromising the aesthetic. To achieve this, we replicated the design of the rear and fabricated a custom front valance panel.

For the rear valance panel, we used 1mm steel plate and reinforced the edge with wire encasement.

Designing the center console was a meticulous task, considering the limited space available for the seats and the operation of the pedal assembly. We carefully crafted a center console that met these precise requirements.

Auto Resto

3/345 Victoria Road, Malaga Perth, Western Australia 6090

If you have any questions, let us know.

Follow us

Copyrights all rights reserved © Zenzi Pty Ltd 2023

![20190131_101430[1].jpg](https://autoresto.com.au/wp-content/uploads/2019/01/20190131_1014305b15d.jpg)